All right, so why a coffee top using plastic? Well the end result is not to have a plastic coffee top, this is just a prototype for something we’re hopefully going to be able to create in glass.

So what’s the idea behind this? Well a friend of mine is super particular about his coffee, so much so that he has expressed that every other type of coffee top has its own set of issues. For instance, paper has a funny taste, plastic becomes stained and disgusting looking (also wasteful), and silicone loses its flexibility and also stains. So what’s really left after all that which is possibly financially accessible to the layman? Glass.

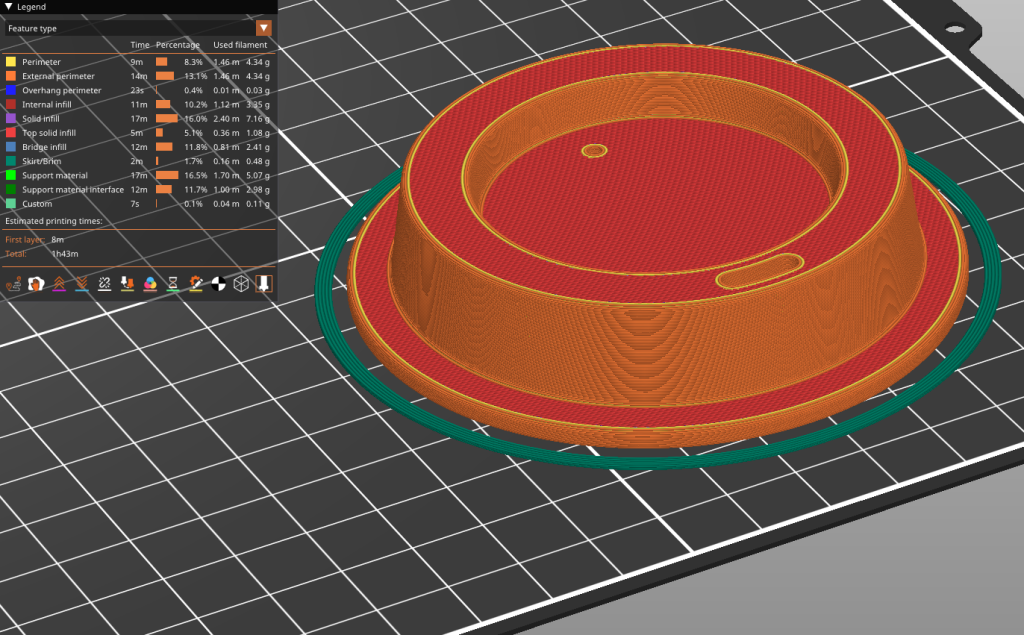

Glass doesn’t stain, or if it does it’s very mild, glass won’t have a funny taste, and it’s incredibly easy to clean. By the way that’s a bad Fusion 360 render on my part, I never used it and I hadn’t tried out. Not impressed. Probably needs drop shadows and all sorts of fancy stuff that we’re probably available in the menus but whatever. If they want people to use it the features should be more obvious! Says the guy using 3D Studio Max which is notorious for hiding features in menus within menus of confusing and unorganized nonsense. I mean the menus don’t even scale still and it’s 2024! Okay, okay. Moving on… But it’s like they don’t even care! Blender is just blowing up the scene and despite 3D Studio Max being one of the earliest 3D modeling softwares it’s just lagging behind. I could write a dissertation… Anyways, back to the topper.

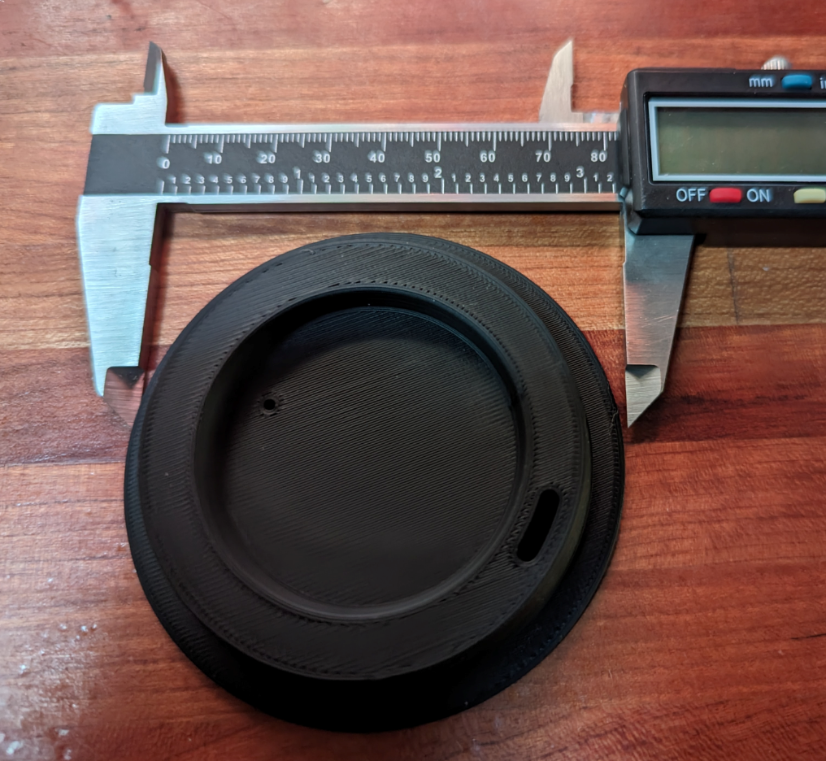

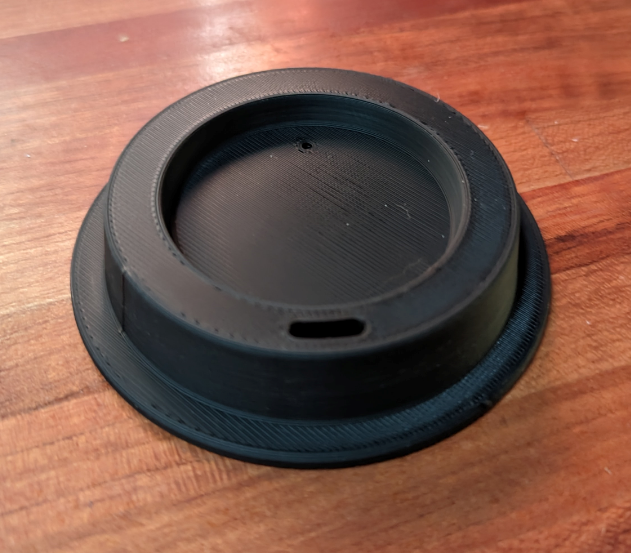

The above picture is my working prototype in plastic. Between the metal screw top and the plastic coffee top is a rubber gasket. Pretty straightforward but not a bad project to break in my new updated printer!

The pictures beloe are some higher print versions that took double the time but are in a galaxy silver PLA material.

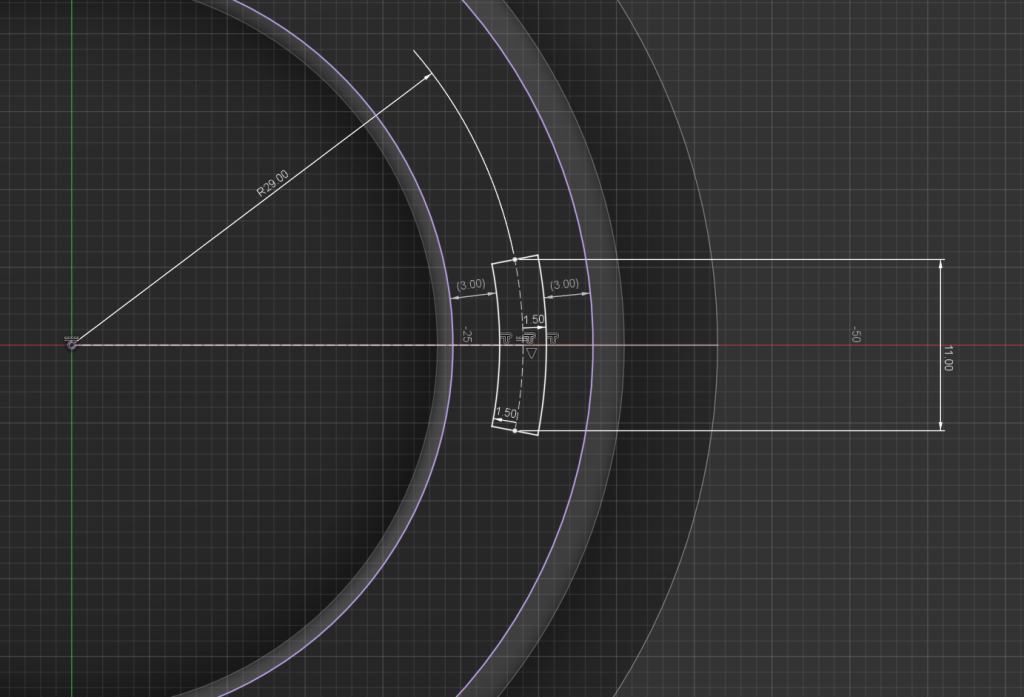

The mouth shape was just a 11 mm arc from a circle that I snapped to the center point so it lined up in the horizontal axis. From there I created an offset Inward and outward by 1.5 millimeters so it was 3 mm total and connected the edges with a line. The mouth shape is beveled on the actual cut into the geometry from extrusion because I don’t like baking in chamfers to sketches. I think it just makes it too messy with all the constraints and trying to keep the measurements concise. So that’s why it looks blocky here but in the actual 3D model it’s rounded off.

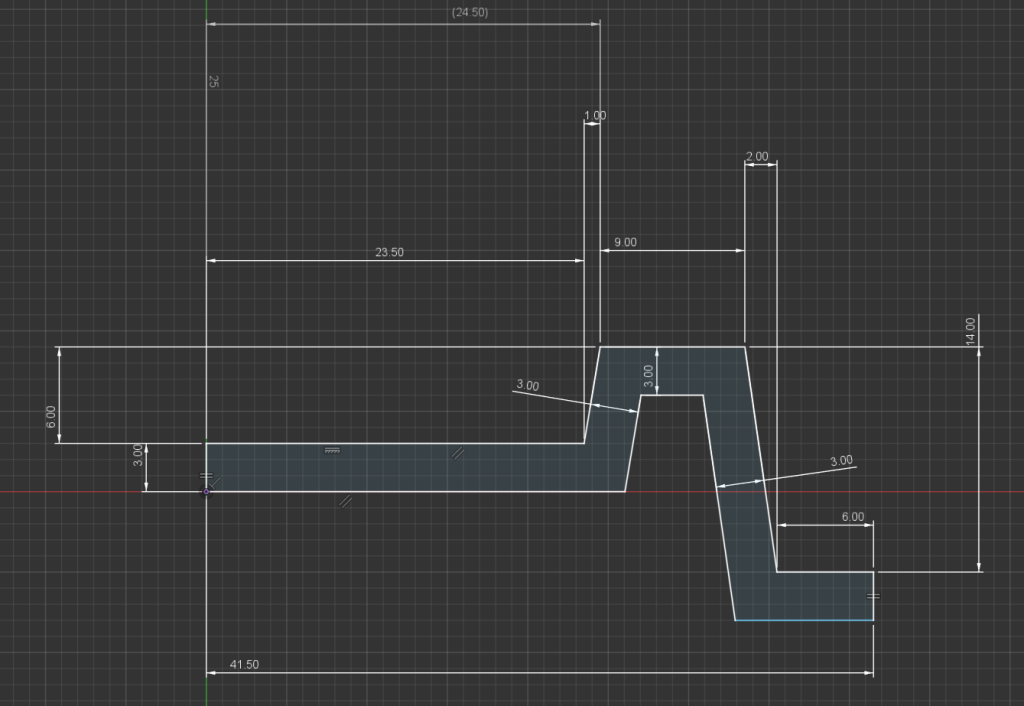

That’s it. Nothing super special, just a a simple lathe of a 2d sketch for the body. The toughest parts are always the constraints but they’re making a lot more sense these days.

Maybe this coffee topper will be my big break so I never have to go back to work. I just finished my second week of a 3 week vacation and I am not looking forward to going back. What a weird sentence.

So anywho, that’s all for now!

-mh